|

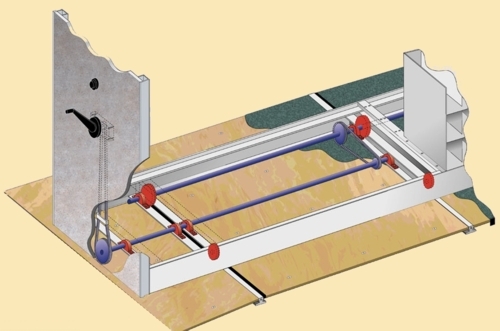

T-SHAPED

STRUCTURAL RAIL

A level rail is

important. We

place leveling

screws on both

sides of the

rail. It is then

precisely

leveled and

under filled

with grout to

form a

concrete-like

strong base.

Each track joins

together

perfectly, like

a model train.

The rails are

end drilled to

accept a 3/8"

steel pin. The

result: Systems

that move

smoothly and

silently. Our

standard rail is

1

1/2" high

and 2

1/2"

wide.

DECK AND RAMP

A Jeter deck

feels solid,

like the floor

underneath it.

Decks are made

of Douglas Fir,

5 ply tongue and

groove, 3/4"

plywood.

Leveling screws

are placed 16"

apart, which

makes our decks

adjustable to

most any floor

condition. All

edges are

finished, and

the deck arrives

ready to receive

the covering of

your choice.

|

|

CENTER DRIVE,

CROSS OVER CHAIN

We also use a

cross over chain

to connect the

two drive

shafts. This

chain is a much

heavier, Harley

Davidson size

chain. It

transfers power

to the drive

line, which

moves all wheels

on one side of

the carriage. By

driving the

system at the

carriage center,

we achieve

perfect, uniform

back and forth

motion. All

sprockets are

welded securely

to the 1" solid

steel shafts.

The shafts are

supported by

heavy-duty

pillow block

bearings, rated

at 1,800 lbs

each. We have

installed over

10,000 systems.

Our mobile

systems are

designed for

long-lasting

reliability.

WELDED

CARRIAGE FRAME

Our strong,

ladder-shaped

carriage frame

is designed to

support a

maximum weight

load of 1,100

lbs per carriage

foot. Our

systems roll

easily due to

the precise

squareness of

the carriage.

The frame parts

are clamped to a

unique fixture,

then welded to a

tolerance within

thousandths of

an inch. Each

carriage is

designed from

12-gauge, .110"

thick 1008/1010

AISI steel.

RECESSED LIP

SAFELY SECURES

CABINETS

Jeter carriages

provide recessed

lips to contain

shelving within

the structure of

the carriage.

This secures the

shelving, so

that it cannot

shift during

carriage

movement. Other

manufacturers

offer carriages

where shelving

"just sits" on

top. With Jeter,

you’ll receive a

system that

offers superior

quality, safety

and reliability.

SERVICE-FREE

CHAIN DRIVE

SYSTEM

All systems come

with a unique,

patented

automatic chain

tensioner. It

adjusts and

compensates for

chain stretch.

This chain

tensioner is a

key component to

ensure your

Jeter system

will remain

service-free ––

for the life of

the system.

CARRIAGES

ROLL

EFFORTLESSLY

Each Jeter

mobile system is

carefully

designed. We

analyze the

weight that will

be placed on the

carriages and

assign the

proper gear

ratio. Our

systems roll on

5" drive wheels,

and guidance is

provided by

flanged wheels

at both ends of

the system. All

center position

wheels are flat.

Our systems move

thousands of

pounds with

truly finger-tip

effort. An

average system

moves 6,000 lbs

with 1 lb of

effort at the

handle –– it’s

easy.

VARIETY OF

END PANEL COLORS

End panels are

offered in a

variety of

colors. The

quality

appearance will

compliment your

office decor.

And, the end

panels close

leaving a 3/4"

gap so that

fingers cannot

get injured. We

design our

systems making

safety first,

always. SAFETY

BRAKES Our

reliable safety

brake is

activated by a

knob above the

handle. Safety

brakes are

installed on

carriages 12" or

longer and on

all x-ray

systems. It is

optional on all

other systems.

STATIONARY

CARRIAGES BOLTED

TO RAIL

Stationary units

are an integral

part of each

Jeter mobile

system. When a

carriage

abruptly hits a

stationary unit,

thousands of

pounds of energy

must be

absorbed. Our

stationary units

are firmly

bolted to the

rail, which is

secured to the

floor. This

guarantees the

perfect

positioning of

rails at the

time of

installation.

QUALITY

INSTALLATIONS

ELIMINATE

SERVICE CALLS

All systems are

thoroughly

reviewed at our

factory prior to

shipment. Each

piece is marked

for correct

placement during

installation.

All hardware for

assembly is

provided,

including carpet

trim to have the

system look

perfect. And,

installations

are completed by

experienced,

factory-trained

service

technicians. |